The smith can also adjust the length and width of the fire in such a forge to accommodate different shapes of work. If a larger fire is necessary, the smith increases the air flowing into the fire as well as feeding and deepening the coke heart. Surrounding all is a ring or horseshoe-shaped layer of raw coal, usually kept damp and tightly packed to maintain the shape of the fire's heart and to keep the coal from burning directly so that it "cooks" into coke first. Around the unburnt coke will be a transitional layer of coal being transformed into coke by the heat of the fire. The heart of the fire will be surrounded by a layer of hot but not burning coke. In operation, the hot core of the fire will be a ball of burning coke in and above the firepot. The tuyere will enter the firepot at the bottom. In a typical coal forge, a firepot will be centred in a flat hearth. Often this involves adjusting and maintaining the shape of the fire. With additional air, the fire consumes fuel faster and burns hotter (and cleaner - smoke can be thought of as escaped potential fuel).Ī blacksmith balances the fuel and air in the fire to suit particular kinds of work. A source of moving air, such as a fan or bellows, introduces additional air into the fire through the tuyere. Traditionally hearths have been constructed of mud-brick ( adobe), fired brick, stone, or later, constructed of iron.ĭuring operation, fuel is placed in or on the hearth and ignited.

Over thousands of years of forging, these devices have evolved in one form or another as the essential features of this type of forge: The forge fire in this type of forge is controlled in three ways: amount of air, the volume of fuel, and shape of the fuel/fire.

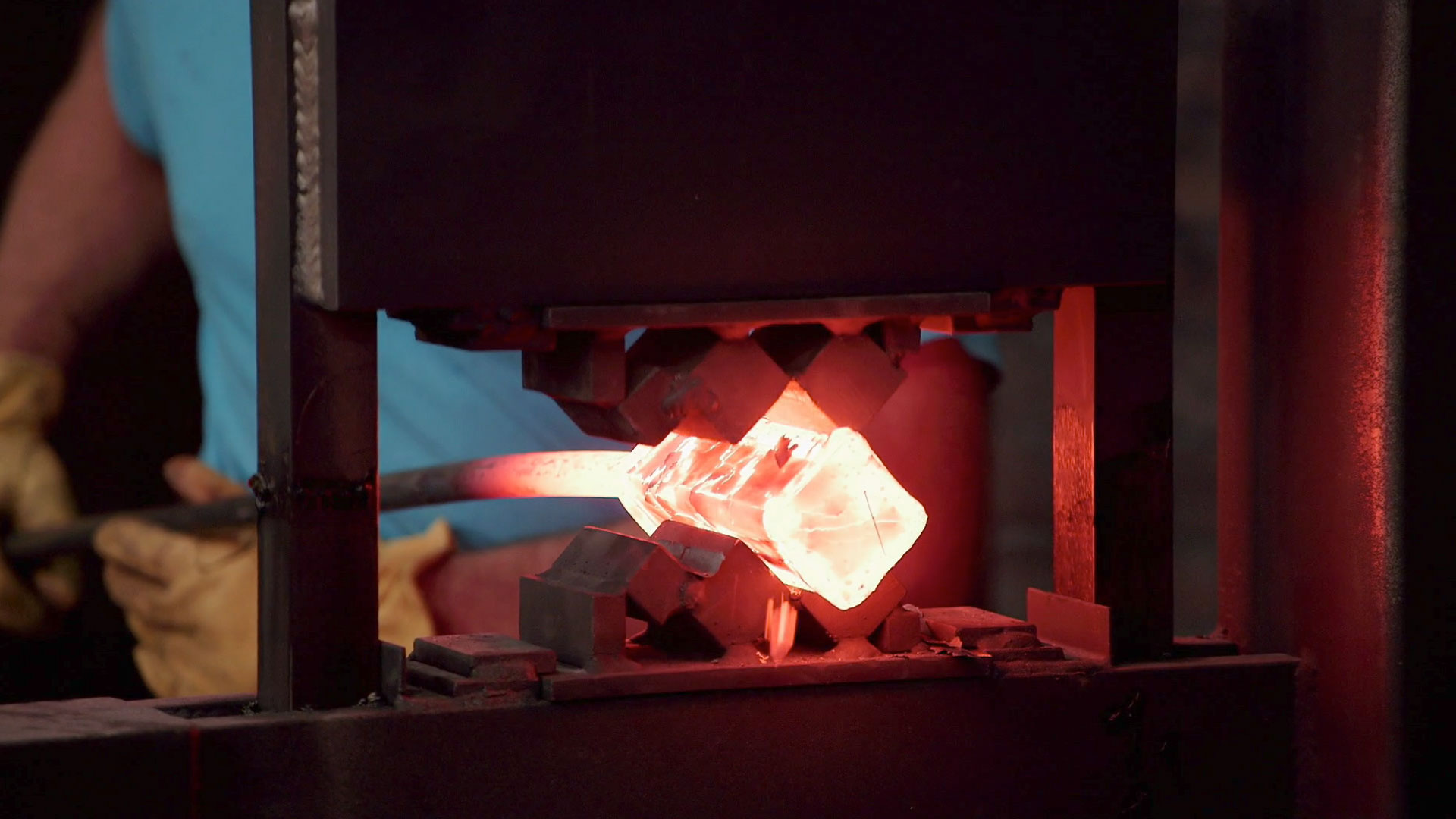

Ī forge of this type is essentially a hearth or fireplace designed to allow a fire to be controlled such that metal introduced to the fire may be brought to a malleable state or to bring about other metallurgical effects ( hardening, annealing, and tempering as examples). The designs of these forges have varied over time, but whether the fuel is coal, coke or charcoal the basic design has remained the same. ( August 2012) ( Learn how and when to remove this template message)Ĭoal/coke/charcoal forge Bottom blast coal forgeĪ forge typically uses bituminous coal, industrial coke or charcoal as the fuel to heat metal. Unsourced material may be challenged and removed. Please help improve this section by adding citations to reliable sources. The slack tub also provides water to control the fire in the forge. However, depending on the metal type, it may require an oil quench or a salt brine instead many metals require more than plain water hardening. Sometimes, such as when hardening steel or cooling the work so that it may be handled with bare hands, the workpiece is transported to the slack tub, which rapidly cools the workpiece in a large body of water. The metal (known as the "workpiece") is transported to and from the forge using tongs, which are also used to hold the workpiece on the smithy's anvil while the smith works it with a hammer.

The forge is used by the smith to heat a piece of metal to a temperature at which it becomes easier to shape by forging, or to the point at which work hardening no longer occurs. The inside of a typical smithy in Finland Wooden smithy built in 1726 in Opole, Upper Silesia, Poland A smithy built around 1880 in Mērsrags, Courland, Latvia currently located at The Ethnographic Open-Air Museum of LatviaĪ forge is a type of hearth used for heating metals, or the workplace ( smithy) where such a hearth is located.

0 kommentar(er)

0 kommentar(er)